Thermoplastic Polymers: A Guide to Plastic Pipes

Plastic generally falls into two types: Thermoplastics and Thermoset materials, in this article we will focus on thermoplastic to answer the frequently asked questions about it and how to use it to manufacture plastic pipes perfectly.

Take a comprehensive look at thermoplastic and complete reading to know the answer to these questions:

- What is thermoplastic polymers, what makes it special?

- What are Some Common Thermoplastic Polymers?

- Thermoplastic pipes: why are they unique & how to manufacture?

- Which types of thermoplastics fits pipes manufacturing?

1- What is thermoplastic polymers, and what makes it special?

“Thermoplastic” is a word that expresses types of polymer resins that becomes soft when heated and can easily reshaped. It becomes hard when cooled.

When thermoplastics exposed to heat, it can be processed through processing techniques such as extrusion, blow molding and injection molding.

Thermoplastics are special because of its unique properties

- Anti-corrosive as they handle corrosive environments.

- They turn to soft material easily by heating, gains strength by cooling.

- They lose its strength by heating.

- Availability in solid form at room temperature.

- The default temperature for thermoplastics is 150ºC.

- They have secondary bonds between its molecules

- They have low tensile strength and low melting points.

- Low-cost production process.

2- What are Some Common Thermoplastic Polymers?

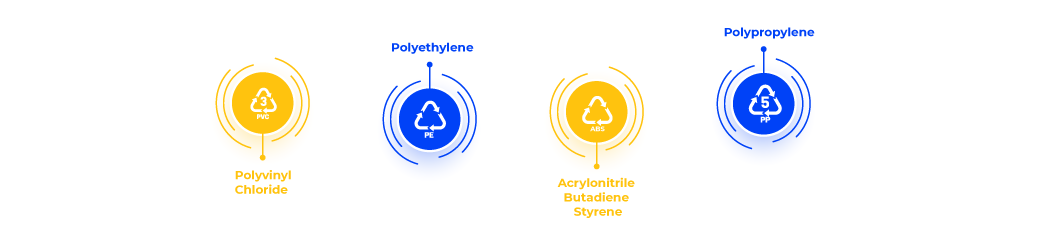

There are thousand types of thermoplastic resins, as you can add fillers and additives to enhance its features. Here are the most used thermoplastics that you can depend on especially for injection molding, but you must define first the best characteristics for your project:

- Polypropylene (PP)

Polypropylene (PP) is a crystalline thermoplastic that manufacturers use widely in everyday products and applications such as household products, packaging trays, medical devices.

PP is used widely in commercial production, as it has special qualifications, such as chemical resistance, flexibility, low electrical conductivity, safety to use on food, low water absorption, and the important one that is PP keeps products’ costs low.

PP has wide range of applications such as Toys, Medical components, Car parts and plastic containers.

- Polyethylene (PE)

Polyethylene is the most important member of polyolefin resins family. It is the most used polymers in the world. It is enough for you to know that the global market volume of PE is expected to reach 130mn metric tons by 2029.

Polyethylene (PE) uses are in grocery bags, packaging films, bottles, pipes, and cables.

- Polycarbonate (PC)

Polycarbonate has unique characteristics such as toughness, transparency, heat & impact resistance, stability and dimensional accuracy, good electrical insulation, and strength.

Polycarbonate is commonly used for greenhouses, car headlight lenses and medical devices.

- Polystyrene (PS)

Polystyrene is created by mixing crystal styrene with rubber. It is low cost and easy to produce.

PS is commonly used in many applications such as lids, containers, trays, and cutlery.

- Polyvinyl chloride (PVC)

PVC is made by suspension polymerization process.it has rigid structure so it withstands with extreme temperatures. It is hard and durable. It can be easily formed; it also has perfect resistance. That’s why it is the perfect material for Pipes manufactures.

3- Thermoplastic pipes: why are they unique & how to manufacture?

.png)

The thermoplastic global market size is expected to reach $4.65 billion in 2021 from $3.29 billion at a CAGR of 5.1 in the forecast period (2021: 2028).

Thermoplastic pipes are the ideal alternative for metal pipes because of many reasons. They are lightweight, non-corrosive, and cost saving.

Polymers manufacturing depends on many factures such as the purpose of the pipes, the material.

There are many ways to manufacture pipes, here are the most common manufacturing ways:

- Injection Molding

Injection molding system depends on heating the plastic resins pellets to molt them. Then it injects them into empty cavity under high pressure. Finally, it opens to eject the final part.

It seems perfect for pipes manufacturing as we can manufacture countless pipes. It can also be affordable in the long run as it is so durable.

- Mixing

This method is done by mixing the resins with an individual blender mounted from the hopper of the extruder, or with the color concentrate in a remote central blender of the extruder.

- Rotational Molding

Rotational molding is about heat. Here we can use the powder form of the resins and put it in a rotating furnace. The plastic powder begins to molt when it touches the mold wall. Finally, you have to make sure that it takes the same shape of the mold.

Rotational molding is considered the most used way to manufacture water tanks as it the simplest way. Its only disadvantage is that you will use only one fixed mold in the rotational molding.

- Extrusion

Extrusion method depends on the extruder which is the main part of this process technique. The extrusion process depends on the shape of the die. It is simply about enriching the raw material with the specific additives, then melting it and forming it continuously.

When it comes to pipes manufacturing, you will start by loading the raw material into the extruder chamber, then you need to heat the material in the barrel up to the recommended heat. You can easily reach the heat up to 200ºC. This high temperature allows the material to reach the right melting point. By this method you can easily shape the material as a pipe when it cools down.

- Bundling

Pipes must be bundled before placing it on the truck. By bundling you can handle loading and unloading easily.

- Fittings manufacturing

Pipes’ fittings can be manufactured manually as the production chains can be automated by cutting.

These smaller pieces that connect the pipes together have complex shapes, so it requires more manual labor.

Worth mentioning that choosing the perfect method depends on the type of material that you will use to manufacture pipes.

4- Which types of thermoplastics fits pipes manufacturing?

- PVC (Polyvinyl Chloride)

When we talk about Pipes, we must talk about Polyvinyl chloride as it the most common used thermoplastic material in pipes. Here is the reason of this connection between PVC and pipes

- PVC offers good quality with its unique properties.

- It has high resistance to alcohols, alkalis, and acids.

- It is light, tough, and flexible.

So, when using PVC in pipes, we get high quality pipes that are dependable and tough. PVC pipes has outstanding resistance to large types of chemicals.

- PE (Polyethylene)

Polyethylene (PE) is widely used to various types of pipes such as natural gas types, drainage lines and drinking water pipes.

Polyethylene is a tough thermoplastic material. It has special properties such as flexibility and light weighting. PE pipes are made by extrusion method and ensures superior flow characteristics.

There are also new developed forms of PE such as PE-RC that offers high crack resistance.

- ABS (Acrylonitrile Butadiene Styrene)

ABS is a cost-effective material that is very popular as an engineering plastic. It is used to manufacture pipes because its high impact strength and rigidity.

- PP (Polypropylene)

It is very suitable for pipes manufacturing because its high chemical resistance, high impact resistance, and good stiffness.

PP can be perfect material for pipes especially grade (PP-R) as it suits high temperature applications such as hot water pipes and industrial applications.

Suggested Blogs

PVC vs PET For Packaging: Which to Choose?

GAP Polymers Team

PET and PVC are two of the most commonly used plastics in packaging applications. Learn the pros and cons of the two materials to determine which to choose.

Food Grade Plastics: FDA Approved Grades

GAP Polymers Team

What are food grade plastics? What are the standards that are set for the safe production and storage of food? Keep reading to discover more.