PET VS PETG: Key Differences

PET VS PETG: Key Differences

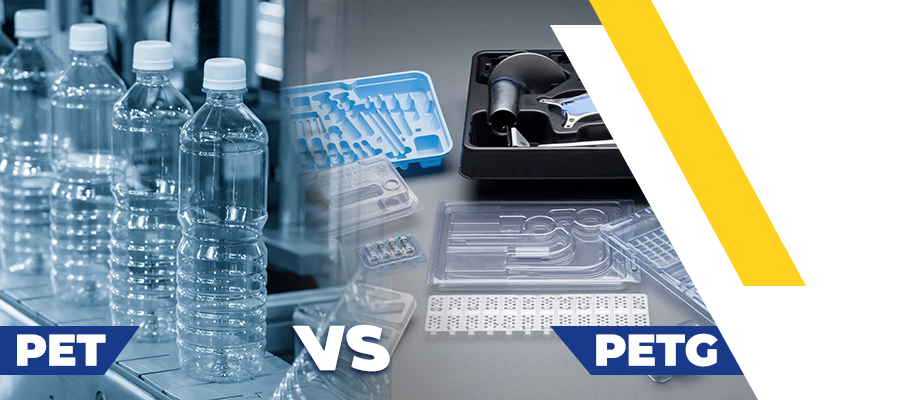

PET (Polyethylene Terephthalate) and PETG (Polyethylene Terephthalate Glycol) are both thermoplastics. They are both transparent and commonly used in many applications.

Increasing demand for PETG materials is becoming remarkably interesting. The global PETG market will increase from $2,7 million in 2023 to $3,8 million in 2033 at a CAGR of 3.3%.s

In this article, we are going to explore how far PET & PETG are different technically.

Our full comparison will cover all the following questions:

- What is PET?

- What is PETG?

- What are the advantages of PETG?

- What are the key differences between PET & PETG?

- What are the main applications of PET & PETG?

- GAP Polymers Guide for main properties of PET & PETG

1- What is PET?

Polyethylene Terephthalate is durable and strong material that becomes ideal for packaging applications, especially bottles. When we mention Pet, we complete the word “bottles” automatically.

As a material, it is known for its transparency, chemical resistance, and high strength.

These unique properties make “PET” the most common plastic material in the world.

In 2022, The global PET market size was valued at $44.30 billion and is expected to exceed $90 billion in the period between 2023 & 2030 at a CAGR of 9.5%.

2- What is PETG?

Have you ever wondered about this extra letter “G”? How can this letter be a factor to choose from the two options?

This “G” stands for “GLYCOL.” It becomes a different material with different usage. It becomes a thermoplastic polyester that provides high chemical resistance and formability during manufacturing processes.

Glycol prevents most PET problems such as cloudiness, fragility, and overheating. The chemical resistance and the absence of odors makes PETG the best for 3D printers.

This amazing copolymer combines the properties of glycol and PET. This will reduce the overheating issues that face manufacturers with PET.

3- What are the advantages of PETG?

PETG offers wide range of advantages, let’s explore them in depth:

- PETG is safe for food contact. It can be used to manufacture drinks bottles and food containers.

- It is easily formable and colored. It can withstand high pressure without cracking. It can be extruded into plastic sheets easily.

- When it comes to coloring, you can color and blend it easily to get various appearances.

- Regarding recyclability, PETG is fully recyclable, which can reduce the environmental impact.

- Additionally, PETG is a cost-effective material while being strong.

- Making the best prototypes and models is simple with PETG printing.

- Due to its UV resistance, you can use PETG for outdoor applications.

4- What are the key differences between PET & PETG?

The 'G' that stands for glycol, is added at the molecular level to “PET” for providing distinct chemical characteristics. Here are the main differences between PET & PETG:

1- Flexibility:

Flexibility is the main difference between the two materials. PETG is more flexible than PET. Glycol addition in PETG makes it less brittle and softer than PET.

That's why PET is perfect for applications that require rigidity and high strength. On the other hand, PETG is ideal for durable and flexible applications.

2- Recyclability:

PET & PETG are both recyclable as they have the same properties. To be fair enough, PETG is more environmentally friendly. Less energy and resources are needed in PETG manufacturing processes.

3- Transparency

Both materials are transparent. PETG is slightly opaque while PET is more transparent. This makes PET perfect for packaging as transparency is necessary.

4- Mechanical properties

PET is a semi-crystalline material that is generally more rigid than PET. PETG is an amorphous material. That's why PETG is more stretcher than PET.

5- Thermal properties

PETG’S crystalline nature makes it good for higher temperatures while PET has more thermal resistance.

6- Prices

PET & PETG are both affordable. The only difference is that you can find PETG in variant colors compared to Polyethylene Terephthalate (PET). On the other hand, PET is chosen when rigidity is necessary.

5- What are the main applications of PET & PETG?

PET Plastic Applications:

Polyethylene Terephthalate is used mainly in packaging applications such as:

- Plastic Bottles

- Mineral water

- Carbonated soft drinks

- Tape applications

- Thermoforming sheets

- Food packaging

- Cosmetic applications

- Electronics

PETG Plastics Applications:

The main application for PETG is 3D printing. PETG filaments offer unique properties such as strength, impact resistance and flexibility.

Because of its low shrinkage properties, PETG is perfect for big and large prints, even better than ABS (ACRYLONITRILE BUTADIENE STYRENE) & PLA (Polylactic Acid). Also, it can be used in food-safe applications that require high temperatures.

Besides these main applications, you can find the PETG in more applications such as:

- Medical applications packaging

- Beverage containers for cooking oils, drinking water and soda

- Mall Displays and stands because of its easy coloring

- Machines protection covers

GAP Polymers Guide for main properties of PET & PETG

|

Property |

PET |

PETG |

|

Impact Strength (J/ M) |

13.34 - 34.68 |

90.8 |

|

Specific Gravity |

1.38 |

1.27 |

|

Tensile Strength (MPa) |

96.5 - 124.1 |

77.2 |

|

Thermal Conductivity (W/ mK) |

0.29 |

- |

The Conclusion:

To choose between these two materials for your project, you must be specific regarding the requirements of the application.

PETG main applications are 3D printing and medical applications, while PET (Polyethylene Terephthalate) is commonly used in Packaging applications.

The two materials offer unique properties, both durable and versatile. They are both affordable and recyclable.

Adding Glycol to PETG gives it unique chemical properties to be perfectly suitable for higher temperatures.

Ready to purchase? Contact Us!

Suggested Blogs

Exclusive vs. Non-exclusive Distributor

GAP Polymers Team

Have you ever wanted to know the difference between the exclusive and the non-exclusive polymer distributers, GAP polymers will help you to know the main differences between them.

An Overview of Polypropylene Thermoforming Process

GAP Polymers Team

PP is the second most popular plastic resin in the world used across many industries. Thermoforming PP has become a process of choice for many manufactures due to its versatility low cost , and more.

Weekly Plastic News & Resins Pricing

GAP Polymers Team

A weekly coverage of all you need to know about the international plastic industry including resin pricing, trends, market insights, and more.

A Deeper Look Into Plastic Manufacturing Industry

GAP Polymers Team

Keep up with the rapid changes of the plastic manufacturing industry and dive deep into what shapes the polymer industry and how to choose the best raw material supplier for your business.

Polymer Industry Updates: What's coming up in 2023?

GAP Polymers Team

2023 is a critical year in the polymer industry at all levels. Global polymers market size is expected to grow finally after the economic recovery from the pandemic.

Top Plastic Raw Material Suppliers

GAP Polymers Team

The polymer industry is facing continues challenges and choosing the best supplier is getting harder. Look no further and explore the full list of the top plastic raw material suppliers.